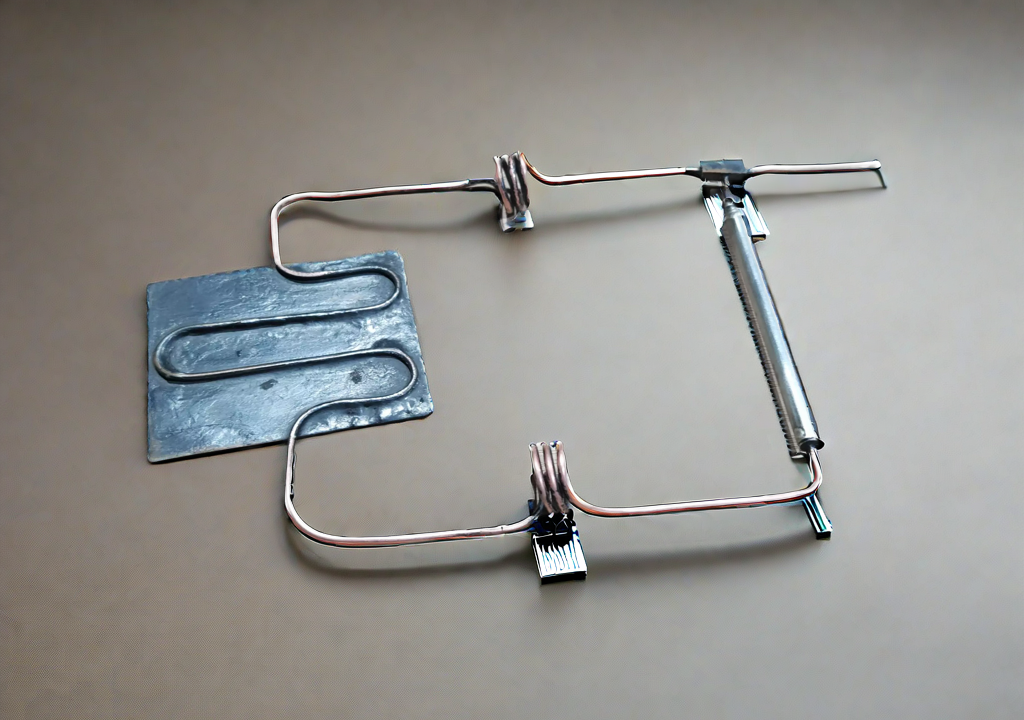

Structure of Loop Heat Pipe

The main disadvantage of Heat Pipes is the decreased heat transfer, especially when the working fluid has to be transported against gravity. To ensure maximum movement against gravity, the capillary head should be at a maximum. The capillary head depends on two variables: surface tension coefficient and the effective pore radius of the wick structure. Capillary head increases with increasing surface tension coefficient and with decreasing effective pore radius of the wick structure. Increasing the surface tension is not plausible, even with water. Decreasing the effective pore radius of the wick structure causes an exponential increase in the hydraulic pressure. Thus, maximizing the capillary head is obsolete in this case. Loop Heat Pipe technology surmounts all these inane solutions.

1. Evaporator: This is the part that receives the heat input. Most of the body of Loop Heat Pipe, including the evaporator, is made of stainless steel owing to the amenability to different kinds of vacuum-hermetic welding and high strength, but they have a low thermal conductivity. Copper can also be used for the construction.

2. Wick (capillary structure): The wick is restricted to that part of the evaporator that receives the heat input. It acts as a capillary pump and a heat exchanger. Wicks are made up of sintered nickel and titanium powders.

3. Working fluid: The ideal working fluid must have a temperature range, suited to the working environment. Ammonia is the most widely used working fluid of the temperature range of -20°C to +80°C.

4. Compensation chamber: This is fitted to the Loop Heat Pipes to accommodate the accumulated working fluid during the operation of the Loop Heat Pipe.

5. Condenser: This part is where the vapors condense dissipating heat, which is delivered to a heat sink.

6. Vapor removal channel: This is fitted to the evaporator end to remove the vapor of working fluid, direct it to the vapor lines which take them to the condenser.

7. Vapour line and liquid line: These are separate smooth-walled lines for vapor and liquid with a relatively smaller diameter.