Thermistance is the first Indian start-up completely devoted to develop advanced passive cooling technologies and its commercialization. Our world class team is continuously working to develop innovative micro and miniature cooling devices. We are also developing our research and development centre in Pune.

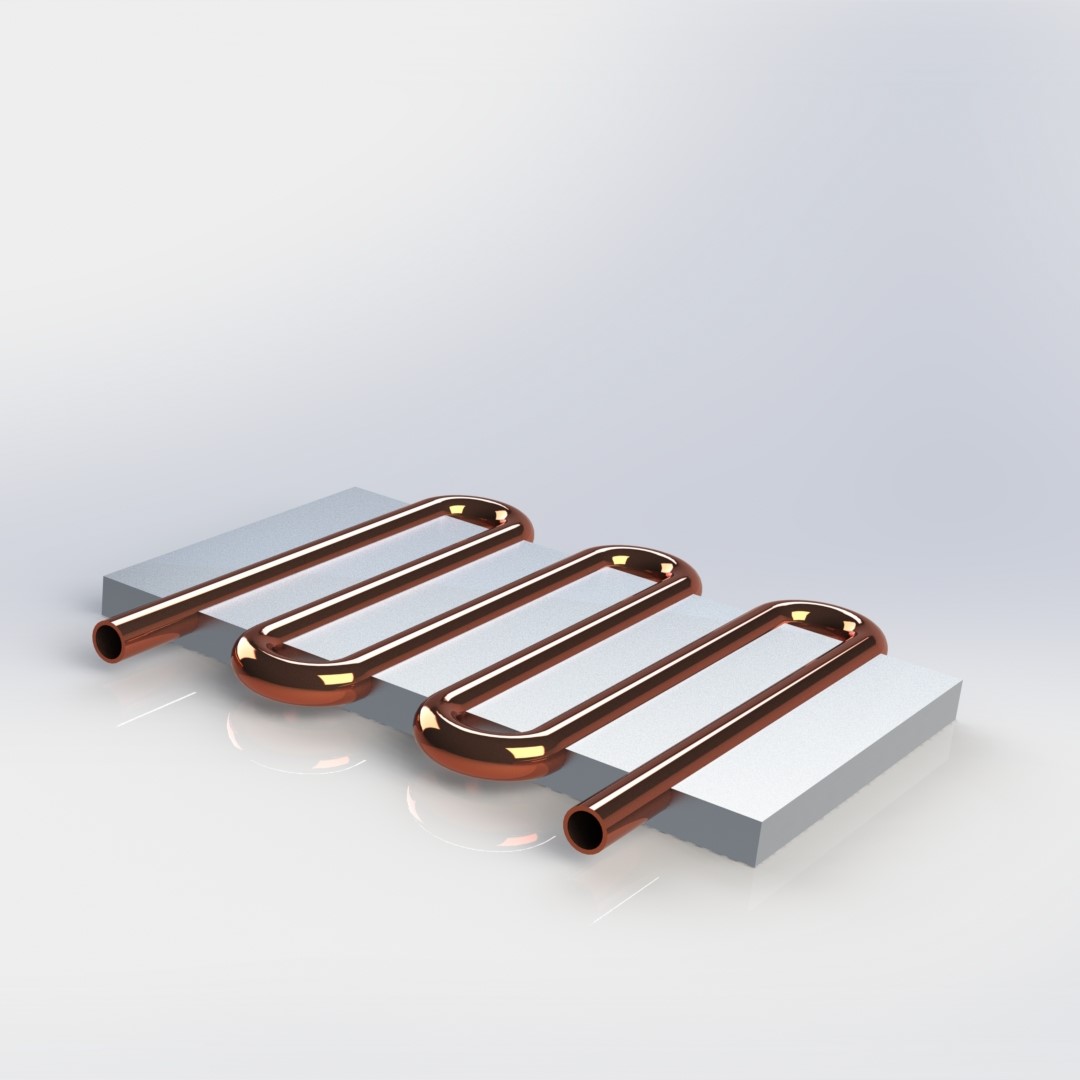

A cold plate is a device used for cooling electronic components, typically in high-performance computing, power electronics, and other applications where heat dissipation is critical. It works by providing a flat, thermally conductive surface that is attached to the heat-generating component. Coolant fluid, such as water or refrigerant, circulates through channels or tubing within the cold plate, carrying away the heat from the component and dissipating it into the external environment.

Cold plates work on the principle of direct liquid cooling through enhanced convective heat transfer. When a coolant fluid flows through the internal channels or microchannels within the cold plate, it absorbs heat from the heat-generating component that the cold plate is attached to.

The design of these channels, often featuring fins, turbulators, or other surface-enhancing features, significantly increases the surface area of the cold plate that comes into contact with the coolant.

This increased surface area allows for more effective and efficient heat transfer from the component to the coolant. The heated coolant then exits the cold plate, transferring the absorbed heat to an external heat exchanger, where it is dissipated into the environment. This continuous cycle ensures that the component remains cool, maintaining optimal performance and reliability.

The working of a cold plate involves a series of steps and mechanisms that enable efficient heat transfer from electronic components to a coolant fluid. Here’s a detailed explanation of how a cold plate operates:

Heat Absorption:

Contact :The cold plate is mounted in direct contact with the heat source (such as a CPU, power electronics, or any other high-heat component).

Conduction :The heat generated by the component is conducted through the material of the cold plate, typically made from a high thermal conductivity material like copper or aluminum.

Fluid Channels :Inside the cold plate are channels or microchannels through which a coolant fluid (such as water, glycol, or a refrigerant) flows.

Convection :As the coolant flows through these channels, it absorbs heat from the walls of the channels via convection. The design of the channels (including any internal fins or microstructures) enhances the surface area for heat transfer, improving efficiency.

Inlet and Outlet :The coolant enters the cold plate through an inlet port, flows through the internal channels, absorbing heat, and then exits through an outlet port.

Pumping System :An external pump typically drives the coolant through the cold plate and the rest of the cooling loop.

High Cooling Efficiency:

High-Performance Computing (HPC):

Cold plates work on the principle of direct liquid cooling through enhanced convective heat transfer. When a coolant fluid flows through the internal channels or microchannels within the cold plate, it absorbs heat from the heat-generating component that the cold plate is attached to.

The design of these channels, often featuring fins, turbulators, or other surface-enhancing features, significantly increases the surface area of the cold plate that comes into contact with the coolant.

This increased surface area allows for more effective and efficient heat transfer from the component to the coolant. The heated coolant then exits the cold plate, transferring the absorbed heat to an external heat exchanger, where it is dissipated into the environment. This continuous cycle ensures that the component remains cool, maintaining optimal performance and reliability.

The working of a cold plate involves a series of steps and mechanisms that enable efficient heat transfer from electronic components to a coolant fluid. Here’s a detailed explanation of how a cold plate operates:

Heat Absorption:

Contact :The cold plate is mounted in direct contact with the heat source (such as a CPU, power electronics, or any other high-heat component).

Conduction :The heat generated by the component is conducted through the material of the cold plate, typically made from a high thermal conductivity material like copper or aluminum.

Fluid Channels :Inside the cold plate are channels or microchannels through which a coolant fluid (such as water, glycol, or a refrigerant) flows.

Convection :As the coolant flows through these channels, it absorbs heat from the walls of the channels via convection. The design of the channels (including any internal fins or microstructures) enhances the surface area for heat transfer, improving efficiency.

Inlet and Outlet :The coolant enters the cold plate through an inlet port, flows through the internal channels, absorbing heat, and then exits through an outlet port.

Pumping System :An external pump typically drives the coolant through the cold plate and the rest of the cooling loop.

High Cooling Efficiency:

High-Performance Computing (HPC):