Thermistance is the first Indian start-up completely devoted to develop advanced passive cooling technologies and its commercialization. Our world class team is continuously working to develop innovative micro and miniature cooling devices. We are also developing our research and development centre in Pune.

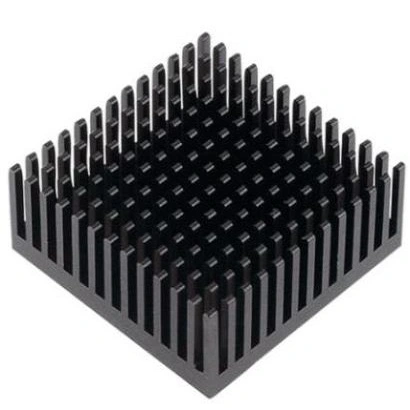

With modern technology at hand, we are trying to tweak every bit of rift we can find in the existing technology. Many devices in use currently, generate a lot of heat. Their heat transfer devices like radiators have the disadvantage of having a sturdy construction. Heat Sink are a modification in the thermal management strategy. They are add ons to the already existing cooling chambers, intending to enhance the area of the chamber exposed. Various geometrical alignments of Pin Fins have been designed, open to even more modifications.

Heat Sinks work on the principle of surface enhancement for effective heat transfer. When the coolant flows through the tubes, subjected to heat removal, they also flow through the Pin Fins that are attached to them. This increases the surface area of the coolant that is exposed to the heat removal device, like a fan. This results in increased heat transfer.

Heat injection: The evaporator receives heat input from the source. This source can be an electronic device or any machinery that generates heat while working. The evaporator injectsheat from source.

Evaporation: The working fluid at the evaporator end evaporates from the wick. Its gaseous form enters the adiabatic chamber.

Vapour pressure increases: The pressure exerted by the vapour over the working fluid increases inside this vacuum sealed cavity.

Latent heat absorbed: When the phase changes at a constant temperature, the resultant release of latent heat is absorbed by the working fluid. As a result, temperature at the evaporator end of the pipe decreases.

Pressure difference: The discrepancy in the pressure between both the ends of the tube is translated by rapid transfer of the vapour to the condenser end, thus equalizing the pressure.

Condensation: On reaching the condenser end, the lower temperature condenses the vapours to the working fluid.

Latent heat released: Condensation of the vapour to the working fluid releases latent heat that is transferred to the condenser end.

Heat sink: From the condenser end, heat if transferred to a heat sink, that releases the heat energy to the environment.

Capillary action: The condensed liquid is absorbed by the wick structure, through which it moves to the evaporator end by capillary action.

Cycle repeats: The entire process is faster than most conventional methods of thermal management. Once the working fluid returns to the evaporator end, and the next wave of heat input is received, the cycle begins again.

1. Low-pressure loss: With Heat Sinks, the pressure loss is greatly reduced which warrants its application in many of the cooling technologies.

2. Heat transfer coefficient: Boiling heat transfer coefficient, condensing heat transfer coefficient are nearly 3 times that of a plain tube..

3. Low maintenance: Pin Fins have a self-cleaning property which makes it easy to maintain.

1. Automobiles: Car engines generate a lot of heat energy. Using Heat Sinks supplemented radiators solves the problem of overheating in cars.

2. Computers: heatsinks enhanced with Heat Sinks have a better cooling down effect.

3. Transformers: The heat loss in a transformer can be efficiently managed by the use of Heat Sinks technology.

4. Hydrogen fuel cells: These cells generate a huge amount of heat that can be counterbalanced with the help of Heat Sinks.

Heat Sinks work on the principle of surface enhancement for effective heat transfer. When the coolant flows through the tubes, subjected to heat removal, they also flow through the Pin Fins that are attached to them. This increases the surface area of the coolant that is exposed to the heat removal device, like a fan. This results in increased heat transfer.

Heat Sink work on the principle of surface enhancement for effective heat transfer. When the coolant flows through the tubes, subjected to heat removal, they also flow through the Pin Fins that are attached to them. This increases the surface area of the coolant that is exposed to the heat removal device, like a fan. This results in increased heat transfer.

1. Low-pressure loss: With Heat Sinks, the pressure loss is greatly reduced which warrants its application in many of the cooling technologies.

2. Heat transfer coefficient: Boiling heat transfer coefficient, condensing heat transfer coefficient are nearly 3 times that of a plain tube..

3. Low maintenance: Pin Fins have a self-cleaning property which makes it easy to maintain.

1. Automobiles: Car engines generate a lot of heat energy. Using Heat Sinks supplemented radiators solves the problem of overheating in cars.

2. Computers: heatsinks enhanced with Heat Sinks have a better cooling down effect.

3. Transformers: The heat loss in a transformer can be efficiently managed by the use of Heat Sinks technology.

4. Hydrogen fuel cells: These cells generate a huge amount of heat that can be counterbalanced with the help of Heat Sinks.